Introduction

Plastic recycling machine selection starts with the sale specification, not the machine catalog. If you define the input stream, the required output spec, and the operating envelope, the correct equipment chain usually becomes obvious.

This page focuses on decision points that affect commissioning risk, product acceptance, and total cost of ownership in North American plants.

Step 1: Define the input stream like an engineer

Most “wrong machine” projects are really “unknown feedstock” projects.

- Polymer(s): single resin vs. mixed stream.

- Form: rigid, film, fiber, foam, purgings, lumps, pipes, drums, etc.

- Contamination: metals, glass, sand/grit, organics, paper, labels, moisture, oils.

- Off-spec risk: PVC in PET, black plastics, multilayer film, aluminum/metallized layers.

- Receiving condition: loose, baled, boxed, or bulk; typical bale density if baled.

If you cannot quantify contamination and variability, specify trials and keep utilities as [SPEC_NEEDED].

Step 2: Define what you sell (output form and acceptance tests)

Pick the output form based on how your customer processes material, then work backward.

- Regrind / flakes: usually sold to compounders or processors with their own filtration.

- Washed flakes: sold when contamination and odor must be controlled before extrusion.

- Pellets: sold when the buyer needs consistent feeding, stable MFI, and tighter contamination limits.

Write down the acceptance tests you and your customer will use (example: moisture method, contamination method, MFI method, odor check). If tests are not defined, disputes happen during commissioning.

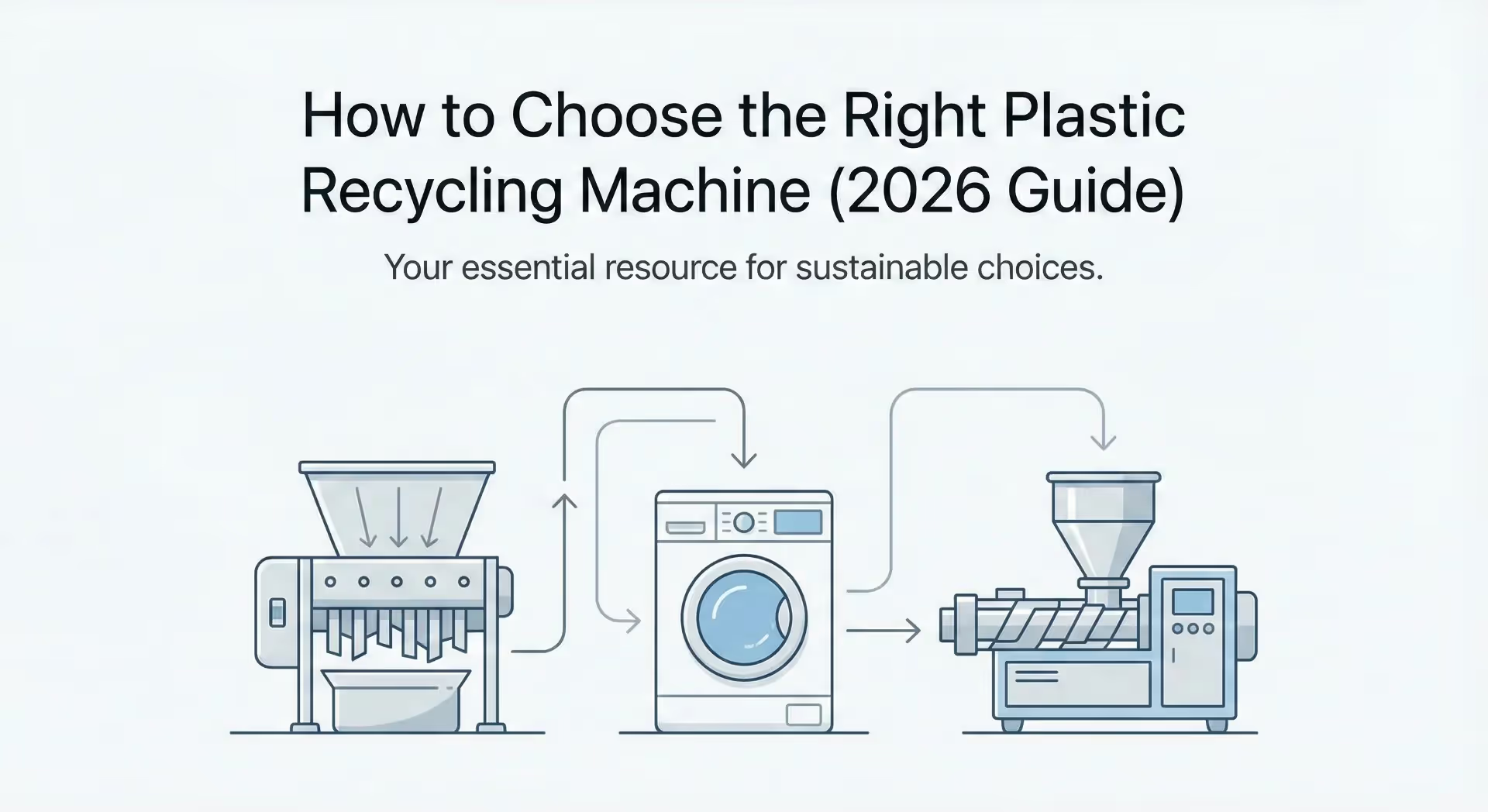

Step 3: Choose the right process blocks (then size them)

A “plastic recycling machine” is a line made of blocks. Choose blocks based on constraints, then size each block to your throughput and uptime requirements.

Common material streams and typical equipment chains

| Material stream | Main constraint | Typical line blocks | Buyer verification focus |

|---|---|---|---|

| PET bottles (post-consumer) | PVC risk, label/glue, moisture control | Debale + sort → wet granulation → label separation → sink/float → hot wash (as needed) → drying → optional extrusion/filtration | Contaminant removal stability over long runs; documented water loop control; moisture measurement method |

| HDPE/PP rigid (post-consumer) | Organics and grit drive odor and wear | Shred/granulate → washing (friction + float/sink) → dewatering/drying → optional extrusion/filtration | Wear strategy for grit; odor control plan; filtration strategy aligned to contamination |

| PE/PP film (post-consumer) | Wrapping, low bulk density, water retention | Bale open → cutting → washing/separation → press/squeezer → densify/compaction → extrusion/degassing/filtration → pelletizing | Mass-flow stability into extruder; dewatering performance; melt pressure trend and screen-change time |

| Post-industrial scrap (clean runners, purgings) | Consistent melt and filtration | Size reduction (as needed) → extrusion/filtration → pelletizing | Feeding consistency; filtration approach; pellet quality stability at target rate |

Step 4: Utilities and footprint (treat missing numbers as risk)

Your best machine choice is constrained by your building and utilities.

- Installed power and typical running load: [SPEC_NEEDED]

- Water circulation and make-up rate (if washing): [SPEC_NEEDED]

- Hot water/steam (if hot wash): [SPEC_NEEDED]

- Compressed air (if used): [SPEC_NEEDED]

- Wastewater discharge limits and sludge handling: [SPEC_NEEDED]

- Building length/width/height and floor loading: [SPEC_NEEDED]

Step 5: Wear parts, maintenance, and uptime reality

The cheapest line on paper often becomes the most expensive line after blade wear, pump wear, and filtration events are accounted for.

- Cutting: knives, screens, knife holders, bearings, and rotor seals.

- Washing: friction washer paddles/liners, pump liners, and tank wear liners.

- Extrusion: screw and barrel wear, screen packs, die plate, pelletizer knives.

Ask the supplier for an uptime-critical spares list and lead times. Treat “spares are available” without lead times as a schedule risk.

Step 6: Supplier qualification (what to demand in writing)

- Trial plan: your feedstock, your acceptance tests, and the run duration required to prove stability.

- Line documentation: PFD, P&IDs, electrical schematics, and a clear I/O list for controls.

- Safety: guarding concept, interlocks, lockout points, and maintenance access plan.

- Service model: commissioning scope, training scope, remote support scope, and response times.

If you plan food-contact applications, align early on the documentation requirements expected in the FDA recycled plastics review process. [1][2]

Repolyx typically provides a commissioning checklist that ties each acceptance metric to a sampling point and test method, because it reduces commissioning disputes.

High-Performance Solutions for Every Stage

From heavy-duty shredders to precision pelletizing lines, explore equipment designed for efficiency and longevity.

View Repolyx EquipmentAt Repolyx, we focus on delivering distinct solutions tailored to your specific material needs. By weighing factors like material type, capacity, and energy efficiency, you can secure equipment that serves your business well for years to come.