Plastic Film Squeezer & Densifier

Plastic film squeezer & densifier (screw-press dryer) for washed PE/PP film - cuts moisture to <5% (typical) and outputs dense granules for Pelletizing. See our Equipment range or request a Quote.

< 5% Residual Moisture for Superior Pellets

Mechanical squeezing, complemented by an optional heated zone, delivers exceptionally low moisture for stable, high-quality extrusion.

Boosted Bulk Density for Higher Throughput

Compacts washed film and bags to optimize conveyor loading and dramatically increase pelletizer throughput.

Unmatched Energy Efficiency

Replace costly and inefficient hot-air drying sections with our powerful high-torque dewatering technology.

Heavy-Duty Construction for Maximum Durability

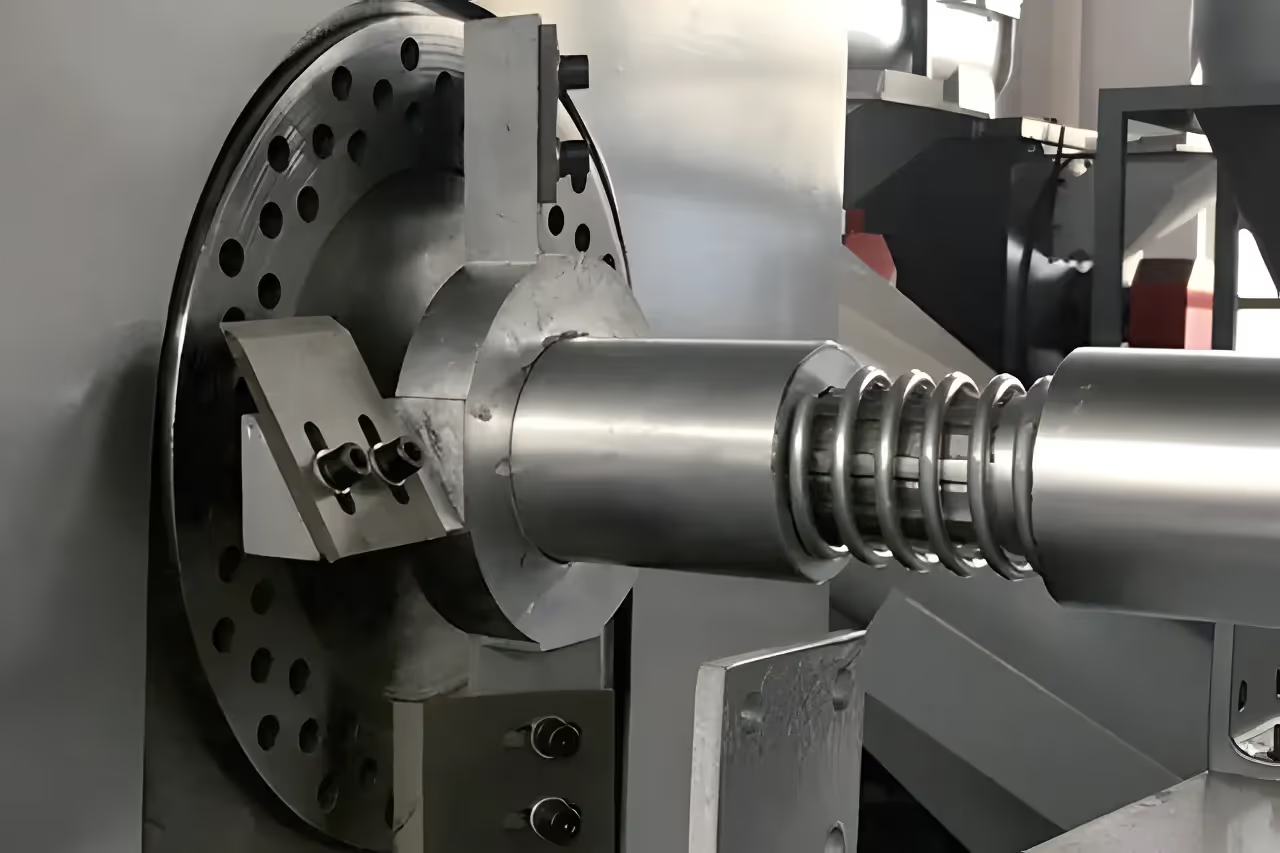

Engineered with a nitrided 38CrMoAlA screw and barrel for superior wear resistance and an extended operational life.

See the Plastic Film Squeezer & Densifier in Action

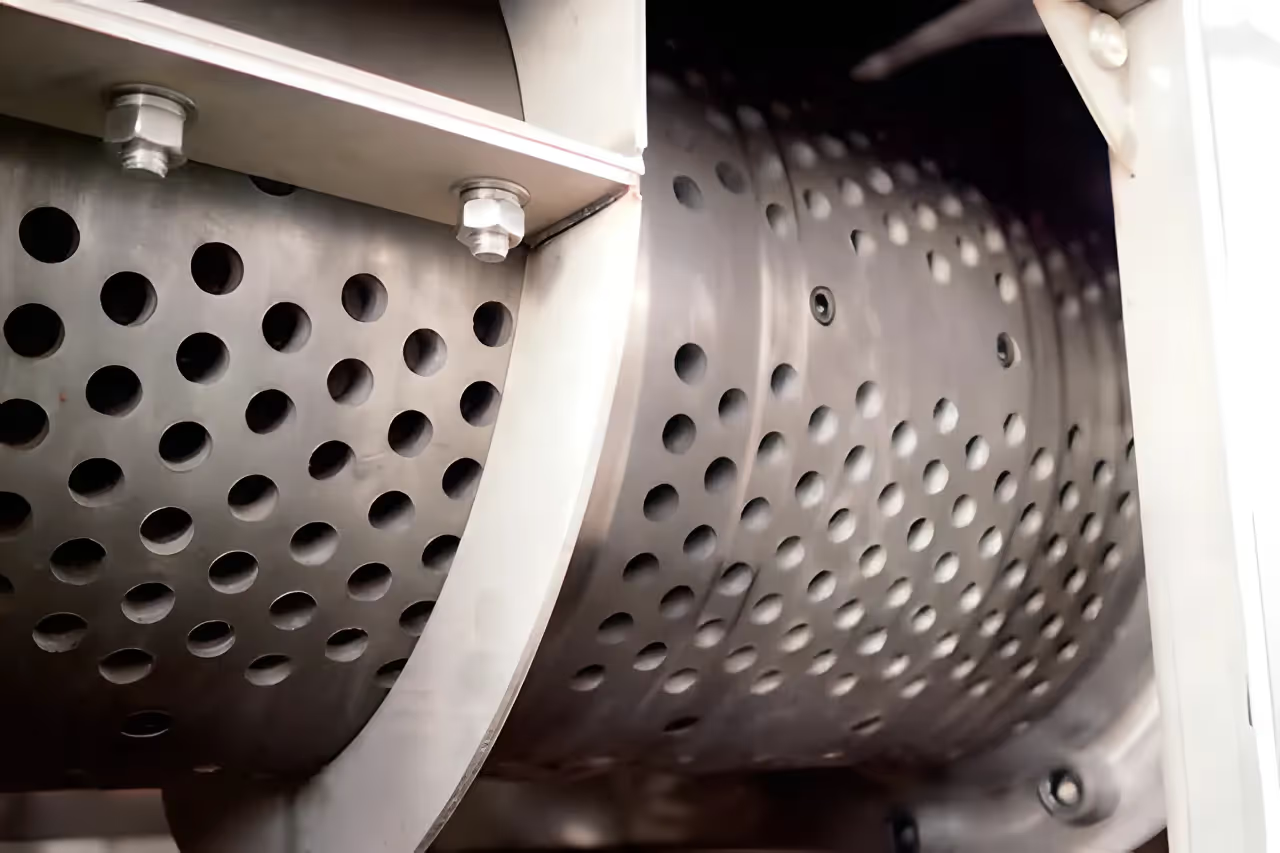

Witness how washed film exits the friction washer and is powerfully compressed inside the perforated barrel. See how the optional heated section stabilizes moisture and produces a dense, uniform discharge, ensuring a steady, high-throughput pelletizing process.

- Achieve low moisture with minimal energy consumption through advanced mechanical squeezing.

- The semi-plasticizing option guarantees superior feed stability for your pelletizer.

- Built to last with a wear-resistant, nitrided screw and barrel for an extended service life.

High-Torque Dewatering and Densification for Peak Performance

Positioned strategically after the final wash and right before pelletizing, our squeezer press reduces or replaces energy-intensive thermal drying. A typical process flow is optimized as: Plastic Film Washing Line → Dewatering Squeezer → Optional Thermal Dryer → Surge Silo → Pelletizing. The perforated barrel rapidly drains water, while the screw's high compression ratio delivers a dense, uniform discharge. Add the heated semi-plasticizing zone to further reduce residual moisture and stabilize the pelletizer feed.

Versatile Processing: Film, Woven & Jumbo Bags

Expertly designed for soft PE/PP materials with high moisture content post-washing.

Advanced Safety Interlocks

Door switches and overload protection are integrated to safeguard operators and protect the drivetrain.

Precision Process Control

Features VFD speed control and precise temperature regulation on the heated zone for consistent results.

Engineered for Easy Serviceability

Replaceable perforated barrel sections and easily accessible bearings minimize downtime and simplify maintenance.

Where It Fits in a Film Recycling Line

- Upstream: Plastic Film Washing Line

- This stage: Mechanical dewatering + densification (optional heated zone)

- Downstream: Surge silo → Pelletizing

Screw Diameter

250–350 mm, tailored to your model

Barrel & Screw Material

Premium 38CrMoAlA, nitrided for exceptional wear resistance

Heated Zone

Optional semi-plasticizing section equipped with high-efficiency electric heaters

Discharge Form

Dense granules/agglomerates, conditioned for stable feeding to your pelletizer

Motor Power

90–220 kW, matched to the model

Heating Power

15–36 kW (optional enhancement)

Capacity

200–800 kg/h, depending on material and initial moisture levels

Target Moisture

< 5% post-squeezing (typical); lower with heated option depending on feedstock

| Model | Screw Dia (mm) | Barrel & Screw Material | Motor Power (kW) | Heating Power (kW) | Capacity (kg/h) |

|---|---|---|---|---|---|

| RTMJG250 | 250 | 38CrMoAlA, Nitrided | 90 | 15 | 200–300 |

| RTMJG300 | 300 | 38CrMoAlA, Nitrided | 110–132 | 22 | 300–400 |

| RTMJG320 | 320 | 38CrMoAlA, Nitrided | 160–185 | 30 | 500–600 |

| RTMJG350 | 350 | 38CrMoAlA, Nitrided | 200–220 | 36 | 700–800 |

Comprehensive Warranty and Lifetime Support: Your Success is Our Priority

Your investment in a Repolyx Systems squeezer is backed by our unwavering commitment to performance and reliability. We provide robust coverage and responsive service to ensure your operations run at peak efficiency.

Standard 1-Year Ironclad Warranty

A full 12-month coverage on all major components and workmanship.

Customizable Extended Coverage

Flexible options for motors, bearings, and control systems tailored to your specific duty cycle.

24/7 Priority Technical Support

Get remote troubleshooting and expert operating guidance precisely when you need it.

On-Site Service & Professional Training

Benefit from professional commissioning, comprehensive maintenance training, and preventative health checks.

Squeezer Applications

Drying and densifying for films, woven bags, and soft plastics.

Washed Film Flakes

Clean PP/PE flakes from washing lines.

Woven Bags

Washed raffia and sack fragments.

Agricultural Film

Mulch film and greenhouse plastics.

Mixed Soft Plastics

Post-consumer LDPE/LLDPE mixtures.

How much moisture is reduced?

Typical reduction is from >30% to <5% moisture after squeezing. With the heated option, many feedstocks can be pushed lower (often ~3%) for more stable pelletizing.

Does it plasticize the material?

It semi-plasticizes the material via friction heat, densifying not-fully-melted popcorn-like granules.

What is the throughput?

Standard models range from 200–800 kg/h, depending on material type, contamination, and initial moisture.

Is maintenance difficult?

Wear-resistant screw and barrel liners ensure long life, with easy access for replacement.