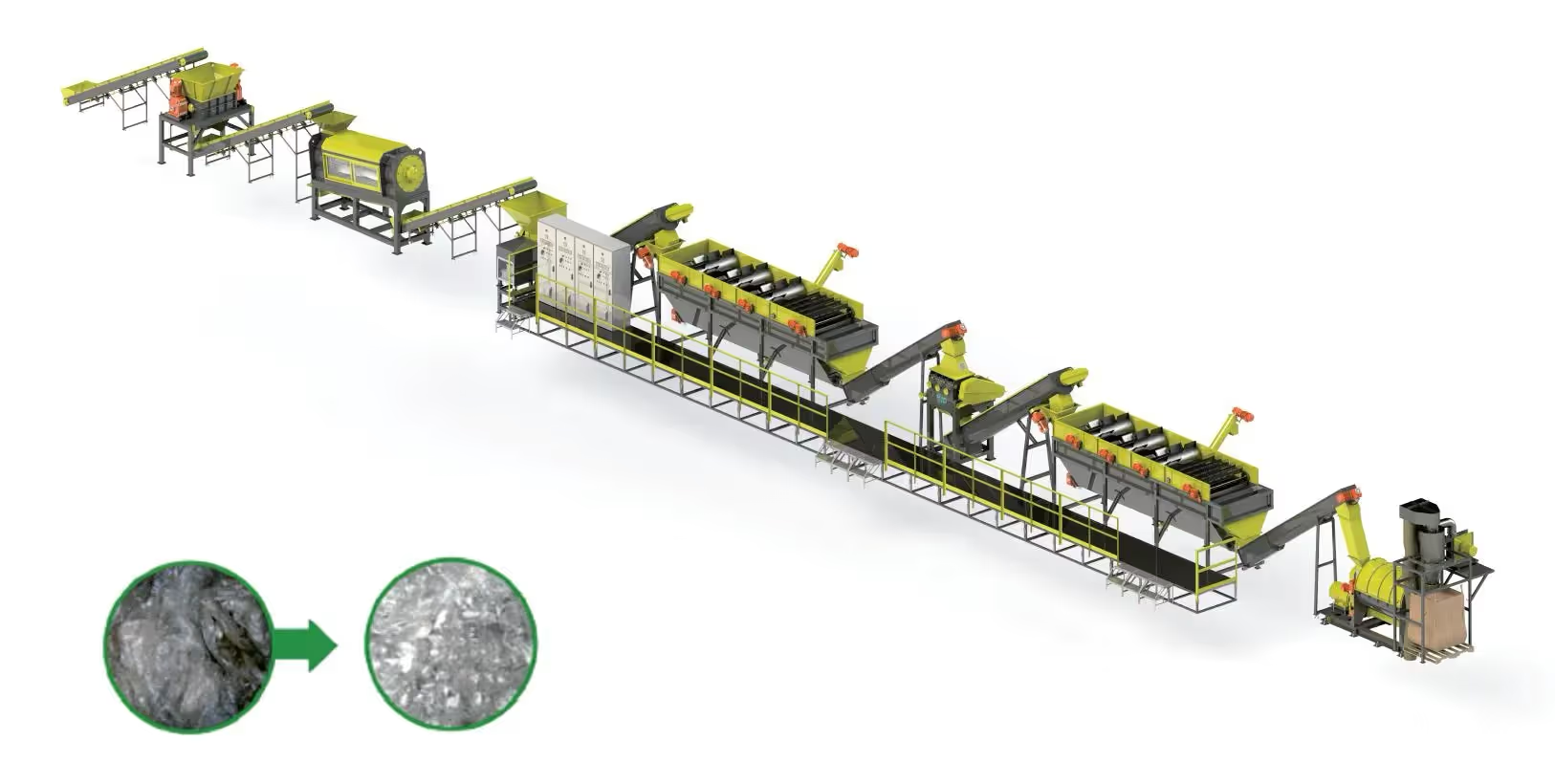

Rigid Plastic Washing Line

Turn contaminated rigid scrap into saleable HDPE/PP flakes with a turnkey rigid plastic washing line built for stable purity at industrial throughput.

- Feedstock: HDPE/PP bottles, caps, crates, buckets, drums

- Capacity: 500 / 1,000 / 2,000 kg/h (customizable)

- Output: clean, low‑moisture flakes for pelletizing or extrusion

Rapid Deployment

Pre‑assembled, factory‑tested modules compress installation time and startup risk.

High Decontamination Rate

Dual friction stages plus optional hot wash and chemical dosing remove labels, oils, and organics.

Resource‑Efficient Operation

Closed‑loop water circuits and steam manifolds with smart controls minimize utility usage.

Operator Safety & Uptime

Guarded access, intuitive HMI, and clear service zones keep crews productive and safe.

See Our High-Performance Rigid Plastic Washing Line in Action

Watch our system process rigid HDPE/PP materials through each automated stage: wet grinding, float-sink separation, optional hot washing, high-intensity friction scrubbing, and final drying. This video highlights how operators use the HMI to monitor system performance and alarms to maintain consistent, high-quality output.

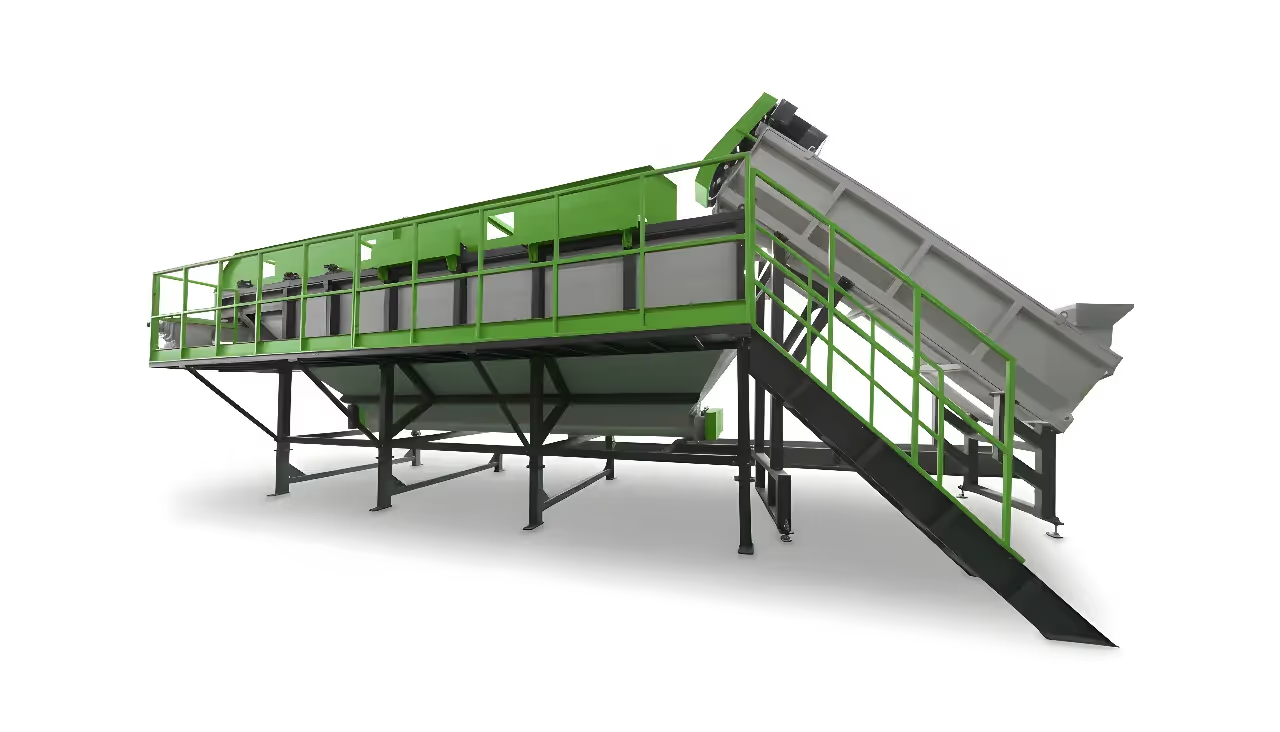

- Efficient float‑sink separation that retains valuable flakes while rejecting labels and fines.

- Inline friction washing with closed‑loop rinse management for low water usage.

- Real‑time HMI insights: amp loads, levels, and alarm history for fast response.

End-to-End Washing & Purification for Rigid Plastics

From infeed to silo, our rigid plastic washing line is configured to hit your required flake purity on HDPE/PP streams with real‑world contamination. Optional hot wash and chemical dosing help remove stubborn adhesives, oil, and organics, while float‑sink separation stabilizes product quality.

Typical process flow: Infeed → Wet crushing → Float‑sink separation → Hot wash (optional) → Friction wash → High‑speed rinse → Centrifugal drying → Air conveying → Storage silo.

Broad Input Compatibility

HDPE/PP bottles, caps, closures, crates, buckets, and injection or blow‑molded parts.

End‑to‑End Automation

Conveyor to silo flow eliminates manual transfers and balances upstream/downstream equipment.

Hot Wash Integration

Optional heated wash with caustic dosing tackles adhesives, labels, and food residues.

HMI Recipes & Alarms

Touchscreen control with recipe recall, trending, and alarm history for fast troubleshooting.

Typical line position

- Upstream: bale opening & sorting → Single‑Shaft Plastic Shredder → wet size reduction via Industrial Plastic Crusher

- Downstream: drying & storage → Plastic Film Recycling Pelletizing Machine (or direct extrusion)

Versatile Material Support

Designed for rigid HDPE and PP streams; supports mixed bottle streams with pre‑sorting.

Advanced Process Control

VFD‑driven motors, level sensing, and PID temperature control for stable washing and drying.

High‑Efficiency Drying

Friction washers and centrifugal dryers deliver low‑moisture flakes ready for conveying.

Throughput Options

Standard lines at 500, 1,000, and 2,000 kg/h; custom capacities on request.

Precision Water Management

Float tanks with adjustable overflow retain flakes while shedding labels and fines.

Durable Construction

304 stainless tanks, wear‑resistant paddles, and sealed bearings for abrasive duty.

Customizable Modules

Hot wash, dosing pumps, remote monitoring, and metal separation to meet local standards.

Seamless Integration

Feeds directly into Repolyx Systems pelletizing, extrusion, and storage systems.

| Capacity (kg/h) | Install Power (kW) | Required Area (m²) | Required Staff | Required Steam (MPa) | Required Water (m³/h) |

|---|---|---|---|---|---|

| 500 | 162 | 500 | 4 | 0.6 – 0.8 | 3 |

| 1,000 | 250 | 800 | 4 | 0.6 – 0.8 | 4 |

| 2,000 | 368 | 1000 | 4 | 0.6 – 0.8 | 5 |

Comprehensive Warranty and Lifetime Support

Every Repolyx Systems system is backed by our commitment to long‑term performance. Protect your investment with robust warranty coverage and responsive expert support.

Standard 1‑Year Warranty

12‑month coverage on major components and workmanship for peace of mind.

Flexible Extensions

Extend coverage for critical elements like motors, control systems, and bearings.

24/7 Technical Support

Round‑the‑clock assistance for troubleshooting, operation, and maintenance planning.

On‑Site Service & Training

Professional installation, commissioning, and operator training for optimal performance.

Genuine OEM Parts

Rapid availability of certified spares to sustain uptime and quality.

Rigid Plastic Applications

Specialized for HDPE/PP bottles, crates, and hard plastics.

HDPE Bottles

Milk jugs, shampoo bottles, and detergent containers.

PP Crates

Logistics crates, pallets, and storage boxes.

Pipes & Drums

HDPE pipes, blue barrels, and industrial drums.

Battery Cases

PP battery casings and WEEE hard plastics.

How much water is consumed?

Our system features a closed-loop filtration unit, recycling >90% of water and reducing fresh water intake.

Can it separate floating contaminants?

Yes, sink-float tanks effectively separate polyolefins (PP/PE) from heavy plastics and dirt.

What is the moisture content?

After centrifugal drying, flakes have <1% surface moisture, ready for extrusion.

Does it remove labels?

We integrate mechanical label removers and hot washing to strip paper and adhesive labels effectively.