Single‑Shaft Plastic Shredder

Single-shaft plastic shredder with hydraulic pusher for bulky rigid plastics. Screened 20-80 mm chips for Crusher and wash lines. See Equipment or request a Quote.

Powerful, Controlled Shredding

Low‑speed (60–100 rpm) rotor with hydraulic pusher delivers high torque and stable feed.

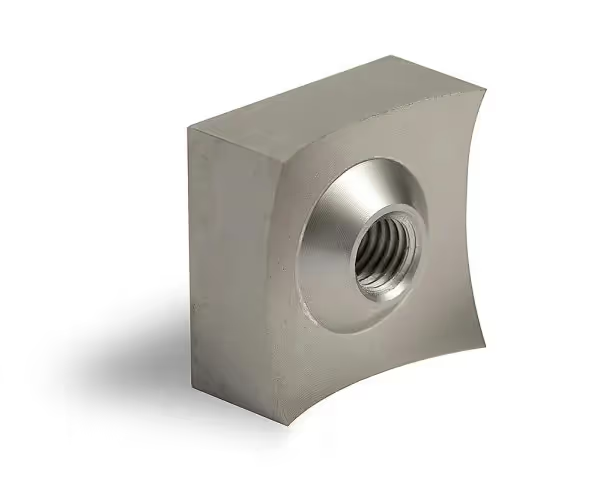

Wear‑Resistant Tooling

Square, indexable SKD11 (D2) knives with hardened counter knives for long life.

Consistent Output Size

Replaceable screens (typically 20–80 mm) define particle size for downstream processing.

Easy Service & Safety

Hydraulic hopper/ram, swing‑out screen cradle, guarded access and interlocks reduce downtime.

See the Single‑Shaft Shredder in Action

Watch controlled, low‑speed shredding of bulky plastics. See how the hydraulic pusher meters material into the rotor and how the screened discharge guarantees consistent particle size for downstream processing.

- Hydraulic pusher keeps material moving for steady load and high torque.

- Square, indexable knives deliver clean cuts and long tool life.

- Screened discharge ensures uniform particles and smoother downstream throughput.

Slow‑Speed, High‑Torque Shredding for Demanding Materials

Built for thick, hard‑to‑cut materials—plastic blocks and sheets, injection runners, buckets and drums, pallet strips, purgings, and PE/PP/PVC pipes—our single‑shaft shredder delivers consistent chip size and high uptime. Compared with high‑speed granulators, it runs quieter and handles bulkier, contaminated feedstock with less risk of jams. The machine can be paired with conveyors and downstream granulators to form a two‑stage reduction line that maximizes throughput and blade life.

Output

Screened chips/flakes (typically 20–80 mm) for stable feeding to crushers, washers, and conveyors.

Best For

Bulky rigid plastics: lumps, pipes, drums, purgings, thick runners, and mixed rigids.

Hydraulic Pusher

Smart load control meters tough materials into the rotor and prevents bridging.

Closed Rotor with Square Knives

Staggered knife layout maximizes bite; knives are bolted for quick indexing and replacement.

Screened Discharge

Material stays in the chamber until it reaches the target size, improving downstream efficiency.

System Integration

Works with belt conveyors, metal detectors, and granulators for two‑stage reduction.

Where It Fits in a Recycling Line

Rotor Speed

Approx. 60–100 rpm (material dependent)

Knife Material

SKD11 (D2) tool steel, heat‑treated and indexable

Counter Knives

Adjustable, hardened; easy shim and alignment

Screen Options

Typical 20–80 mm, custom apertures on request

Drive Power

22–180 kW across models (higher on twin‑drive versions)

Hydraulic Unit

Variable‑speed pusher with pressure control

Chamber Sizes

600–3000 mm rotor length options

Throughput

Material and screen dependent; share kg/h target + feedstock for a tailored estimate

| Model | Rotor Dia (mm) | Rotor Blades | Motor Power (kW) | Chamber Width (mm) |

|---|---|---|---|---|

| RTM‑SS600 | 220 | 28 | 22 | 600 |

| RTM‑SS800 | 360 | 36 | 37 | 800 |

| RTM‑SS1000 | 380 | 58 | 45 | 1,000 |

| RTM‑SS1200 | 400 | 76 | 55 | 1,200 |

| RTM‑SS1500 | 450 | 106 | 75 | 1,500 |

| RTM‑SS2000 | 450 | 162 | 2 × 55 | 2,000 |

| RTM‑SS3000 | 500 | 192 | 2 × 90 | 3,000 |

Comprehensive Warranty and Lifetime Support: Your Success is Our Priority

Your investment in a Repolyx Systems shredder is backed by our commitment to performance and reliability. We provide robust coverage and responsive service to keep your operation running at peak efficiency.

Standard 1‑Year Ironclad Warranty

Full 12‑month coverage on major components and workmanship.

Customizable Extended Coverage

Flexible options for motors, bearings, hydraulics, and control systems.

24/7 Priority Technical Support

Remote troubleshooting and operating guidance when you need it.

On‑Site Service & Professional Training

Commissioning, maintenance training, and preventative health checks.

Shredder Applications

Heavy-duty shredding for lumps, pipes, rolls, and purge patties.

Plastic Lumps

Purge patties, heavy chunks, and extruder start-up lumps.

Pipes & Profiles

Thick-walled HDPE pipes and PVC profiles.

Woven Bags

Jumbo bags, raffia, and big bags.

Film Rolls

Compacted film rolls, BOPP rolls, and stretch film.

What is the knife mechanism?

We use rotatable hardened square knives (4 edges) for extended service life and easy replacement.

Does it have a pusher?

Yes, a hydraulic ram pusher automatically feeds material against the rotor for consistent throughput.

What screen sizes are available?

Screens are customizable from 20mm to 100mm depending on desired output size.

Can it handle metal contamination?

The drive system protects against overload, but we recommend upstream metal detection for rotor safety.