Industrial Plastic Crusher

Heavy-duty industrial plastic crusher for HDPE/PP/PET rigids—screen-controlled flakes for washing lines. See our Equipment range or request a Quote.

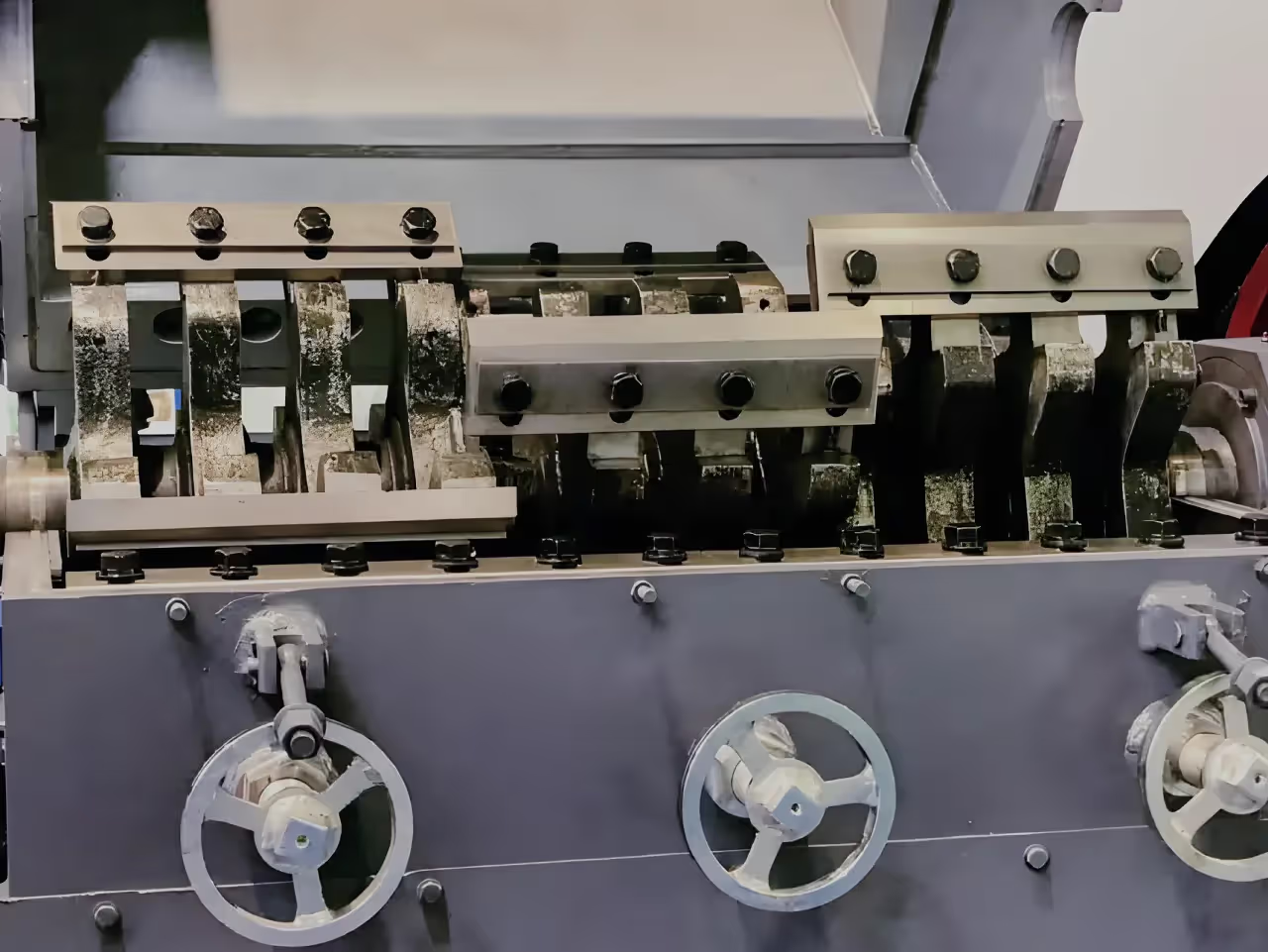

Configurable Rotor Shaft

Different shaft structures are available to suit various plastic materials and wall thicknesses.

Open Bearing Seats

Open‑type bearing housings make assembly, disassembly, and maintenance fast.

Movable Screen Drawer

Slide‑out screen for quick install/uninstall and aperture changes.

Electric Chamber Cover

Power‑assisted cover opening for safe, easy blade changes and cleaning.

Continuous Operation

Robust cooling and bearing design support 24/7 non-stop running without overheating.

Anti-Blocking Design

Optimized V-cut rotor geometry ensures smooth ingestion and prevents material bridging.

See the Industrial Crusher in Action

Watch rigid HDPE/PP parts crushed into uniform flakes. The movable screen drawer and electric cover opener simplify service, and the optional wet kit reduces dust while improving wash efficiency.

- Configurable rotor shaft for different plastics and thicknesses.

- Open bearing seats and electric cover for fast maintenance.

- Movable screen drawer for quick aperture changes.

Built for Uptime, Easy for Maintenance

The Light/Heavy Series Crusher provides flexible setups for different feedstocks. Choose rotor diameters and knife arrangements to match your parts.

Quick‑change screens and accessible knife seats reduce downtime and keep throughput stable.

Output

Uniform flakes (screen-controlled) for stable washing and reprocessing.

Application

Rigid plastics (HDPE, PP, PET, PS, PVC), bottles, crates, sprues, and pipes.

Throughput

Sized by model, feedstock, and screen; share your target kg/h for a capacity recommendation.

Safety Interlocks

Door switches and overload protection safeguard operators and drivetrain.

Screen Apertures

Φ12–Φ100 mm standard; other sizes available.

Optional Wet Kit

Integrated water feed for dust suppression and pre‑rinsing.

Where It Fits in a Recycling Line

- Upstream: Conveyor or Shredder

- This stage: Crusher for size reduction into flakes (screen-controlled)

- Downstream: Washing or PET lines; optional Pelletizing after drying

Rotor/Crushing Diameter

Φ450–Φ680 mm depending on model

Moving/Fixed Blades

2×3 moving per row; 2×2 fixed typical (see table)

Screen Aperture

Φ12–Φ100 mm

Drive Device

Electric motor with V‑belt transmission

Motor Power

22–110 kW by model

Drive Unit Power

1.1 kW auxiliary (screen/cover drive)

Feeding Mouth

600×700 to 600×1200 mm

Dimensions

2160×1620×2900 to 2230×2020×2900 mm

| Model | Motor Power (kW) | Moving Blades (pcs) | Fixed Blades (pcs) | Crushing Rotary Dia×Len (mm) | Feeding Mouth (mm) | Screen Aperture (mm) | Drive Device | Drive Unit Power (kW) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|---|---|

| PCS600 | 22/30 | 2×3 | 2×2 | Φ450×600 | 600×700 | Φ12–Φ100 | Electric | 1.1 | 2160×1620×2900 |

| PCS800 | 37/45 | 2×3/2×5 | 2×2 | Φ580×800 | 600×1000 | Φ12–Φ100 | Electric | 1.1 | 2230×1820×2900 |

| PCS1000 | 55/75 | 2×3/2×5 | 2×2 | Φ580×1000 | 600×1200 | Φ12–Φ100 | Electric | 1.1 | 2230×2020×2900 |

| PCS1200 | 90/110 | 2×3/2×5 | 2×2 | Φ680×1200 | 600×1200 | Φ12–Φ100 | Electric | 1.1 | 2230×2020×2900 |

Comprehensive Warranty and Lifetime Support

Your crusher is backed by Repolyx Systems's commitment to performance. We offer robust coverage and responsive service to sustain uptime.

Standard 1‑Year Warranty

12‑month coverage on major components and workmanship.

Extended Coverage

Options for motors, bearings, and control systems based on duty cycle.

24/7 Technical Support

Remote troubleshooting and operating guidance when you need it.

On‑Site Service & Training

Professional commissioning, maintenance training, and health checks.

Versatile Material Processing

Engineered to handle a wide variety of rigid plastic waste streams.

HDPE/PP Rigid

Bottles, crates, drums, pallets, and pipes.

PET

Beverage bottles, preforms, and thermoforms.

PVC

Window profiles, pipes, and construction scraps.

PS/ABS

Electronic housings, appliance parts, and trays.

Can this crusher process plastic films?

Yes, but it is optimized for rigids. For films, we recommend installing the optional wet kit to prevent overheating and improve cutting efficiency.

Is the output particle size stable?

Yes. The particle size is determined by the screen aperture (Φ12–Φ100mm). The machine recirculates material until it passes through the screen.

Can I customize the voltage?

Absolutely. We supply motors compatible with your local power grid (e.g., 220V/60Hz, 380V/50Hz, 480V/60Hz).

How does the machine integrate into a line?

Upstream: Conveyor, Shredder, or manual feeding. Downstream: Friction washer, dewatering, silo, and Pelletizing after drying.